Rapid quench technique

Motivation

Investigation of melt properties is more complicated than that of solid. Therefore, the quench of melt to glass is a practical strategy to investigate the properties of silicate melts. However, it becomes more challenging to quench melt to glass with decreasing SiO2 content and increasing pressure and volatile contents. Therefore, we are making efforts to expand the pressure and composition ranges of silicate melt by increasing the quench rate.

Strategy

The rapid quench technique was established based on the following three strategies.

Effective heat exhaust

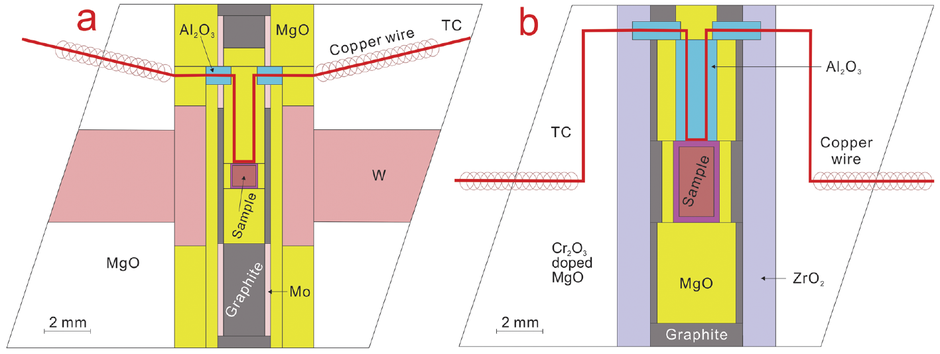

In usual multi-anvil assemblies, the heater is surrounded by a thermal insulating sleeve made of a low thermal conductivity material, such as ZrO2 and LaCrO3, to increase the heating efficiency. However, such a setting lowers the quench rate. Therefore, we replace the thermal insulator with a sleeve made of high thermally conductive and highly refractory material, tungsten (Fig. 1a, 1c). Furthermore, the tungsten sleeve is connected to six inner anvils by tungsten rods to make paths of heat exhaust (Fig. 1a, 1c).

Figure 1. (a) Cross section of the rapid-quench multi-anvil assembly, (b) standard 18/8 assembly, (c) simplified 3D model of a low thermal-inertia assembly. TC - thermocouple.

Small heat production.

It is essential to decrease the heat production rate to increase the quench rate at a given heat exhaust rate. Therefore, the heater and sample dimensions are minimized for the pressure medium dimensions. The difference in the sample and heater dimensions between the rapid-quench and standard cells is evident by comparing Figure 1a (rapid quench) and 1b (standard).

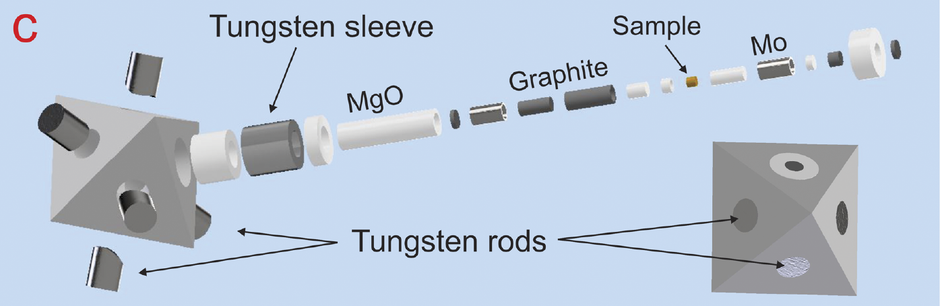

External cooling.

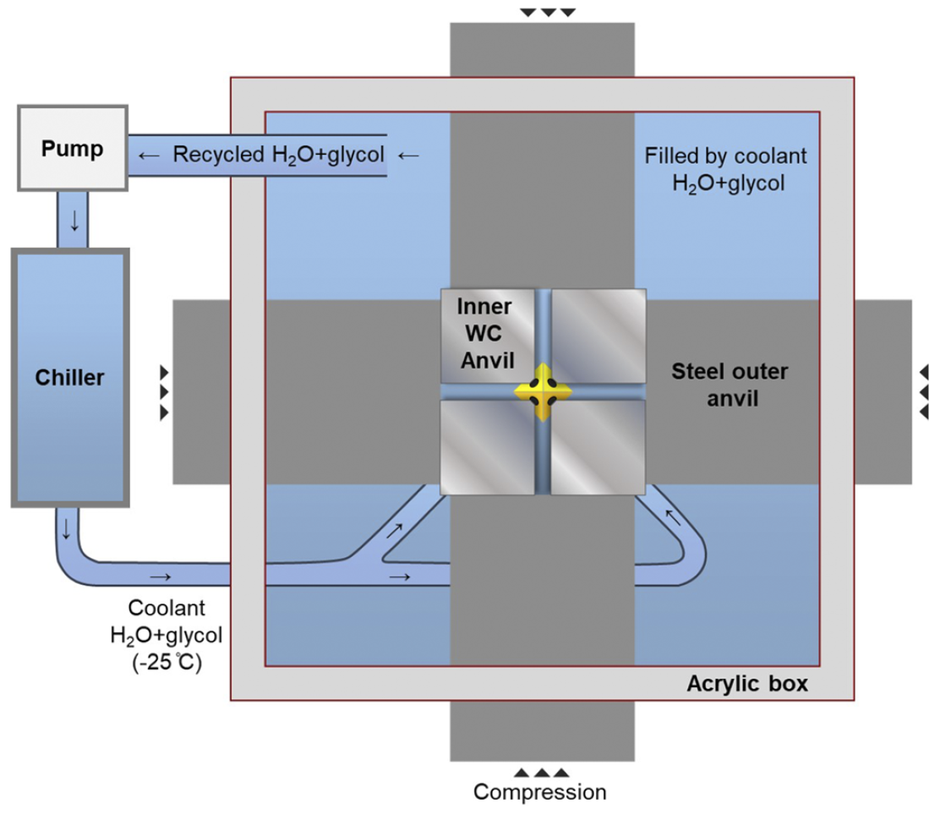

Since the heat flow is proportional to the temperature gradient, making the outside temperature as low as possible is essential. Therefore, we cool the assembly using a -20℃ coolant circulated in an acryl box by a chiller (Fig. 2, 3). The coolant is a 1:1 mixture of water and ethylene glycol. The liquid nitrogen is not used because the thermal insulation of the box is limited.

Figure 2. General scheme of the cooling system.

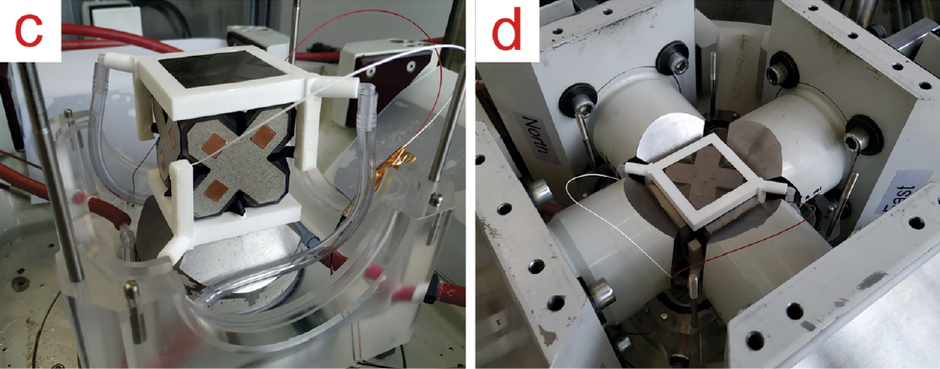

Figure 3. Photos of (a) the acrylic box with hoses, (b) the chiller, (c) and (d) the construction process of the cooling system.

Performance

Cooling rate.

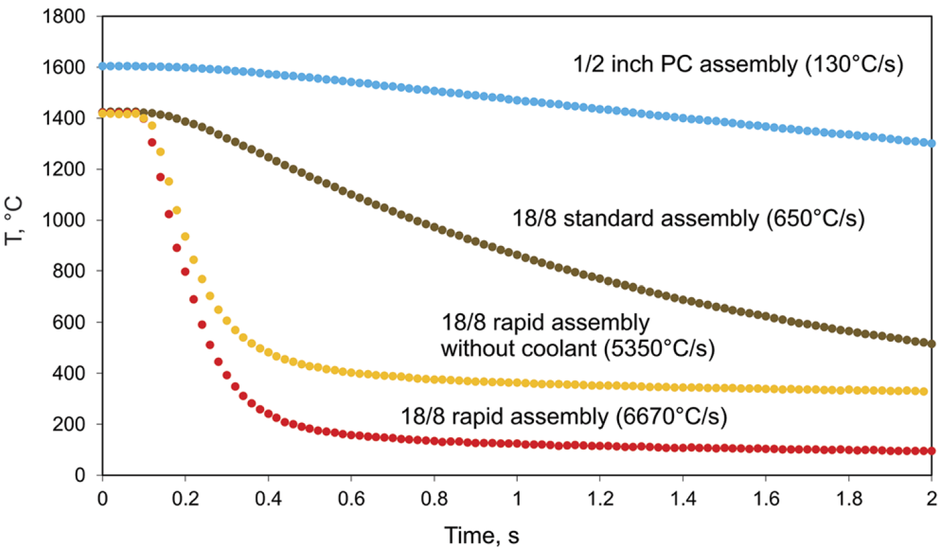

Figure 4 shows a comparison of cooling rates of different types of assemblies. Although the cooling rates of the conventional assemblies of piston-cylinder and multi-anvil are the order of hundred ℃/s (130 and 650℃/s), those of the rapid quench assembly are 5000~7000℃/s, by one order of magnitude higher. The external cooling system enhances the cooling rate by 12%.

Figure 4. Comparison of cooling rates among different assemblies. Each data point represents an average of 50 measured values. The value 6670℃/s is an average from four experiments. There is a 0.1 s offset of cooling profiles for clarity. PC: piston-cylinder.

Glass synthesis.

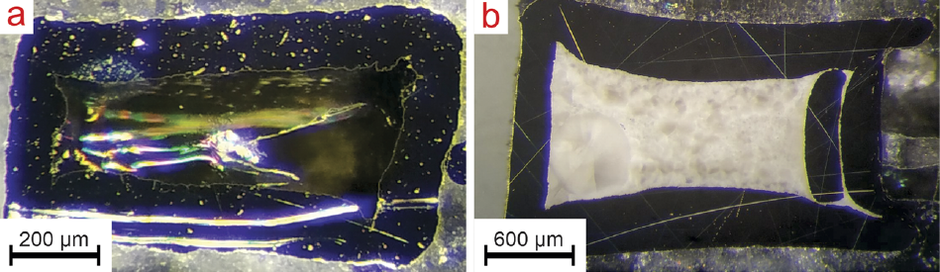

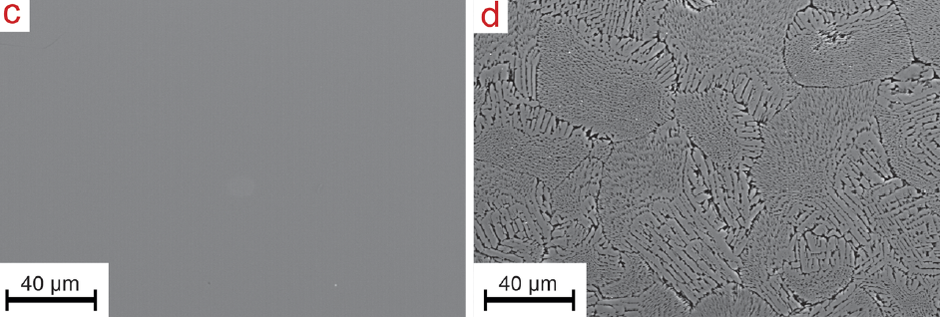

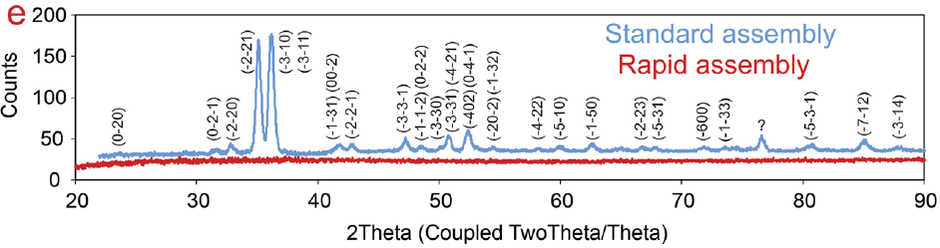

To examine the quenching capability of the rapid quench assembly. We attempted to quench a molten hydrous silicate melt with a composition of 70% basalt and 30% peridotite with 2% water from a temperature of 1420℃ at a pressure of 4 GPa. Figure 5a shows a transparent glass produced by the rapid quench assembly, whereas Figure 5b shows a white quench crystal mixture produced by the standard assembly. Figures 5c and 5d are backscattered electron images of these samples showing homogeneous and dendritic textures. Figure 5e shows their diffraction patterns, demonstrating that the products of the rapid quench and standard assemblies are amorphous and olivine crystals, respectively.

Figure 5. (a, b) Optical images of run products made by the rapid and standard 18/8 assemblies respectively, (c, d) images of run products in backscattered electrons from a and b respectively, (e) X-ray diffraction patterns of the run products from a and b.

Remarks

The rapid-quench technique has increased the cooling rate by one order of magnitude and produced a hydrous ultramafic glass that could not be produced previously. Previously, high pressures, volatile components, and ultramafic compositions prevented from quenching a melt to glass, but we can overcome these difficulties. We will investigate the properties of various melts and glasses using this technique.

Publications

Bondar, D., Zandonà, A., Withers, A.C., Fei, H., Di Genova, D., Miyajima, N., Katsura, T., Rapid-quenching of high-pressure depolymerized hydrous silicate (peridotitic) glasses, J. Non-Cryst. Solids, 578, 121347, 2022.

Bondar, D., Fei, H., Withers, A.C., Ishii, T., Chanyshev, A., Katsura, T., A simplified rapid-quench multi-anvil technique, Rev. Sci. Instr., 92, 113902, 2021.

Bondar, D., Fei, H., Withers, A. C., Katsura, T., A rapid-quench technique for multi-anvil high-pressure-temperature experiments, Rev. Sci. Instr., 91, 065105, 2020. Article in Scilight